How to optimize the waterproof performance of aluminum alloy system doors and windows through drainage structure design?

Release Time : 2025-09-25

The key to optimizing the waterproof performance of aluminum alloy system doors and windows lies in the scientific and systematic design of drainage structures. The design logic must be based on a "combination of drainage and blocking" approach, requiring both sealing to prevent rainwater infiltration and constructing efficient drainage channels to ensure that any small amount of seepage is quickly discharged, preventing backflow or stagnation. In this process, the application of the isobaric principle, the rational layout of drainage holes, and meticulous detailing all contribute to the key support for waterproof performance.

The isobaric principle is the core theoretical foundation of the drainage design of aluminum alloy system doors and windows. When aluminum alloy system doors and windows are closed, an isobaric cavity is formed between the window sash and the frame. Drain holes are designed within the profile's outer cavity to maintain equilibrium between the air pressure within the cavity and the outside air pressure. This design ensures that rainwater, under its own gravity, drains through the drainage holes along the pre-defined path to the window frame sump, where it is then discharged outdoors through the diversion structure, rather than accumulating within the profile. For example, some high-end aluminum alloy system doors and windows feature concealed drain channels on the outside of the window frame. These vertically directed drain holes reduce the risk of rainwater backflow while also preventing the holes from being exposed and affecting the aesthetics.

The layout of drain holes directly impacts drainage efficiency. Traditional exposed drainage solutions, with holes drilled directly below the window frame, are simple in structure, but can easily lead to overflow during heavy rainfall due to insufficient drainage capacity. The improved concealed drainage solution utilizes raised grooves in the window frame profile and places the drain holes above them, leveraging water pressure differentials to enhance drainage capacity while also concealing the holes for improved aesthetics. Floor drain drainage is a further improvement, with holes drilled simultaneously at the bottom and outside of the window frame, connected by specialized drain hole covers. This achieves both water-stopping and the "whistling effect" caused by strong winds, making it particularly suitable for high-rise buildings or areas prone to extreme weather.

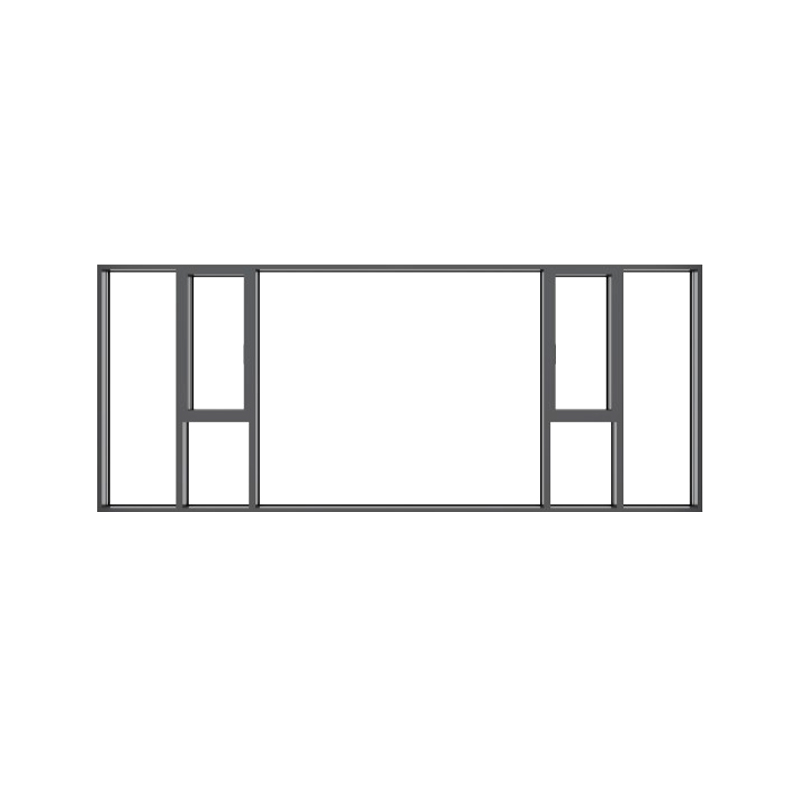

Detailed design is the "last mile" of waterproofing performance. For example, a drip cornice prevents rainwater from flowing along the profile wall into the interior due to surface tension. The overlap between the window frame and sash features an open-gap design, maintaining pressure balance inside and outside the drain hole and ensuring smooth drainage of rainwater under gravity. A sheathing plate is installed on the upper portion of the movable sash, while drain holes are located below, creating a three-dimensional barrier that blocks rainwater from above and drains it from below. Furthermore, the guide rail design of sliding aluminum alloy system doors and windows requires optimization. By providing drain ports on both sides of the rail and a square through-hole in the center, a complete "infiltration-diversion-drainage" path is created to prevent rainwater from accumulating within the rail.

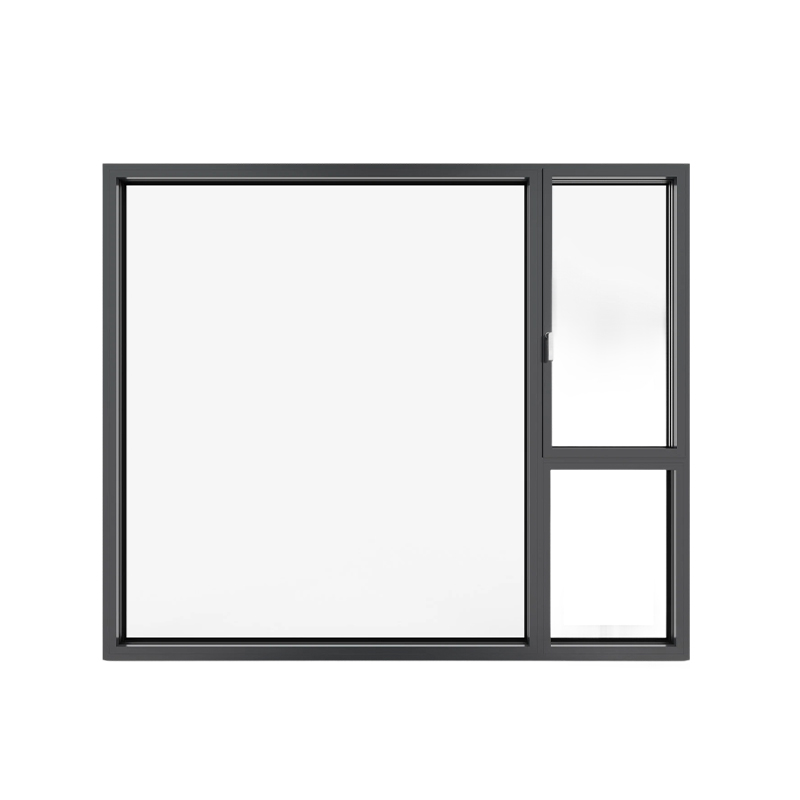

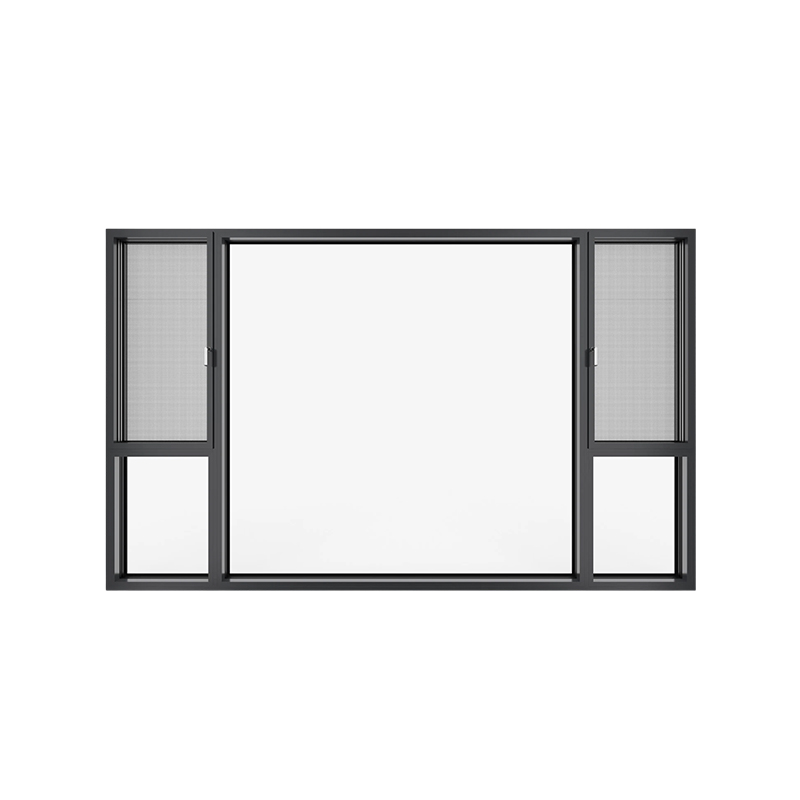

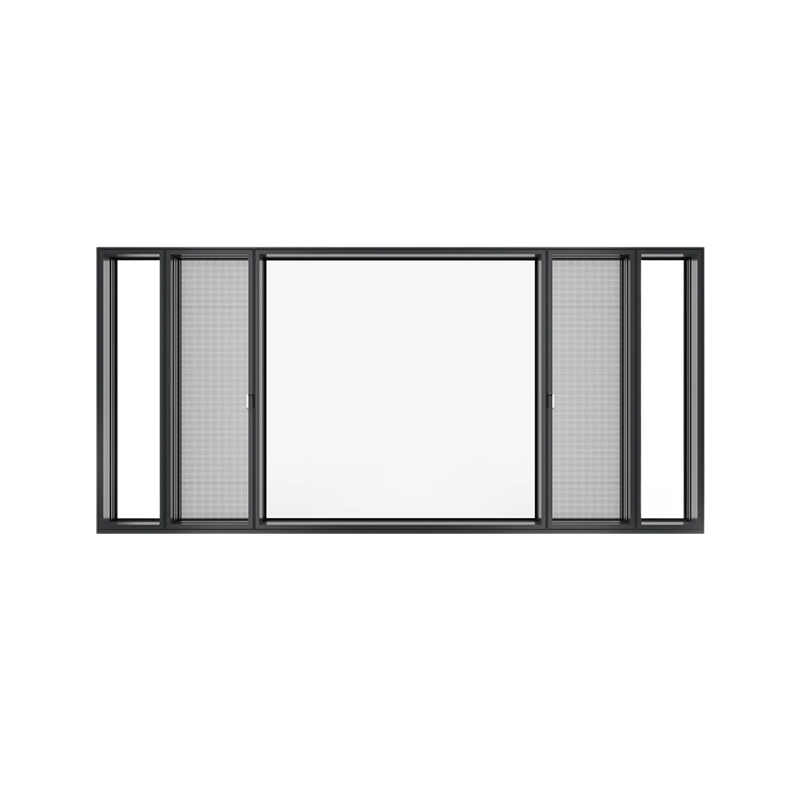

Aluminum alloy system doors and windows with different opening methods have different drainage design requirements. Due to their structural characteristics, sliding aluminum alloy system doors and windows create a gap between the sash and the rail. This requires the addition of airtight seals and wind deflectors to reduce air leakage. Furthermore, the drainage structure should be optimized, such as by providing drain ports on the outer rail and square through-holes on the inner rail, to ensure that any rainwater that does seep out can be quickly drained. Casement aluminum alloy system doors and windows rely on multiple layers of sealing strips to create an isobaric chamber, while drain holes on the outside of the window frame allow for rapid drainage. When combining aluminum alloy system doors and windows, it's important to minimize exposed joints. If this is unavoidable, the profile contact surface at the joint should be designed at 90 degrees to facilitate sealant injection and prevent rainwater infiltration.

Material and process selection are also crucial. Sealing strips should be made of age-resistant, elastic EPDM rubber to ensure long-term cracking. Drain hole covers should be constructed of zinc alloy composite material to extend their service life and prevent insects and termites from entering. Profile machining precision must be strictly controlled to prevent leaks due to joint gaps. During installation, the gap between the window frame and the wall should be fully filled with waterproof mortar or polymer cement mortar, and a slope should be installed on the outside to prevent rainwater backflow. After installation, a spray test should be conducted to simulate a heavy rain environment to verify drainage effectiveness and ensure there are no potential leaks.

Optimizing the waterproof performance of aluminum alloy system doors and windows requires comprehensive control of the entire process, from design principles and drainage solutions to detailed treatment, material selection, and installation techniques. By scientifically applying the principle of equal pressure, rationally arranging drainage holes, optimizing detailed design, matching opening characteristics, rigorously selecting materials and processes, and strengthening installation quality supervision, a three-dimensional waterproofing system combining waterproofing and drainage can be established, effectively adapting to complex climates and ensuring the long-term stable operation of aluminum alloy system doors and windows.