What are the advantages of the Low Energy Consumption Inward Opening Window System (LEI) for aluminum alloy doors and windows?

Release Time : 2025-10-11

Excellent Performance: Setting the Energy-Saving Standard Through Five-Performance Testing

The LEI's aluminum alloy doors and windows have passed authoritative five-performance testing (wind pressure resistance, watertightness, airtightness, thermal insulation, and sound insulation), achieving industry-leading performance. Its wind pressure resistance reaches Level 9 (the highest level), capable of withstanding a Category 12 typhoon; its watertightness reaches Level 6 (the highest level), ensuring no leakage for 10 minutes in a simulated rainstorm; and its airtightness reaches Level 8 (the highest level). Its airflow rate is only 0.5 m³ per square meter per hour, far lower than the 1.5 m³ of ordinary doors and windows. Its thermal insulation performance is also Level 9, with a K value (heat transfer coefficient) as low as 1.1-1.3 W/(m²·K), saving over 60% energy compared to ordinary aluminum alloy windows (K value 6.69-6.84 W/(m²·K)). With a sound insulation rating of Level 4, it can block noise levels exceeding 35 decibels, making it suitable for noise-sensitive areas such as airports and high-speed rail stations. For example, in cold northern regions, the Low Energy Consumption Inward Opening Window System can reduce indoor heating energy consumption by 30%, saving up to 1,500 kWh per household annually.

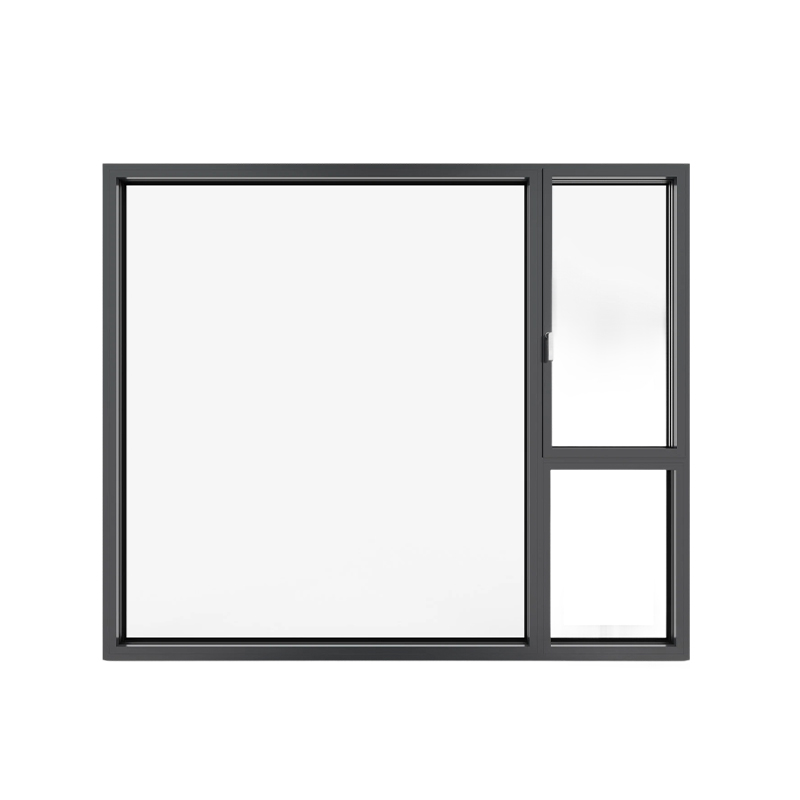

Structural Innovation: Synergistic Optimization of Quick-Installation Hardware and Thermal Insulation Strips

The Low Energy Consumption Inward Opening Window System utilizes next-generation quick-install concealed hardware technology. Its single sash has a load-bearing capacity of 180 kg, far exceeding the 80 kg limit of traditional hinges, enabling stable installation of large glass expanses (up to 6 square meters). The unique thermal insulation strip design with single or double fins physically blocks the heat transfer channel in the profile, improving its thermal insulation performance by 40% and increasing its bending resistance by three times, effectively addressing the problem of deformation in large windows. The window sash and frame corners are assembled using a pin-injected glue process, achieving a bond strength twice that of traditional corner brackets, ensuring long-term wear and tear, providing dual protection against heavy glass loads and strong winds and heavy rain. The triple-seal + trailing sealant strip structure, with soft-hard co-extruded composite sealant strips (soft for elasticity, hard for durability), improves airtightness by 50%. The trailing design further optimizes thermal insulation and reduces cold bridge formation.

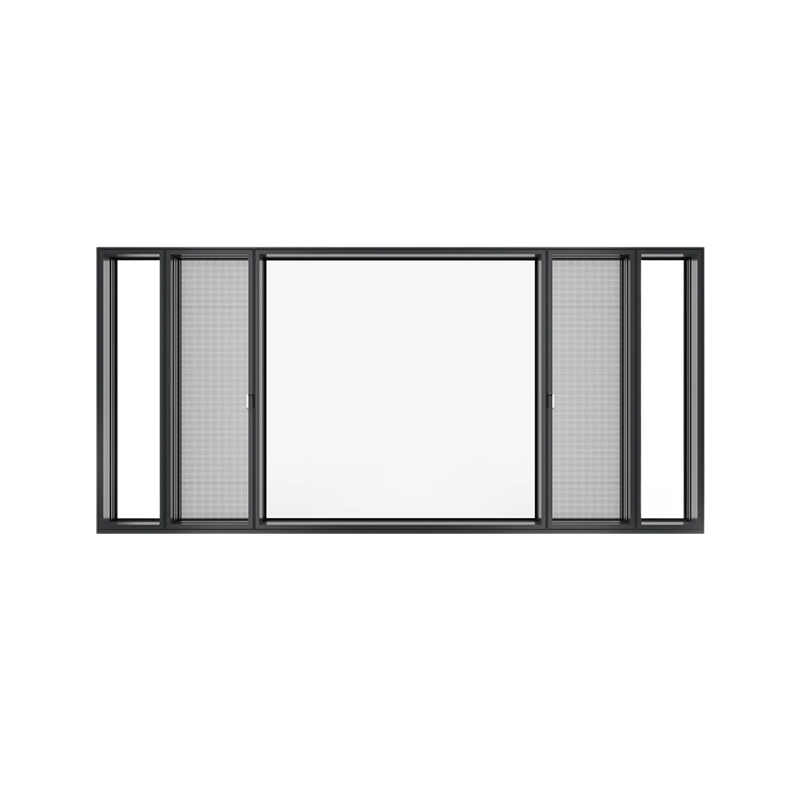

Energy Savings Furthered: Technological Breakthroughs in Triple-Glass, Double-Cavity, and Drainage Systems

The Low Energy Consumption Inward Opening Window System supports a triple-glazed, double-cavity structure (5mm glass + 12mm hollow layer + 5mm glass + 12mm hollow layer + 5mm glass). The K value of the entire window can be reduced to 0.8W/(m²·K), saving 20% compared to double-glazed structures and accommodating temperatures as cold as -30°C. Concealed or high-efficiency exposed drainage channels direct rainwater outdoors through rapid drainage channels, eliminating the clogging problems of traditional exposed drain holes while maintaining a clean facade. For example, in a residential project in Harbin, the adoption of a triple-glazed, double-cavity structure reduced indoor temperature fluctuations from ±5°C to ±1.5°C in winter, reducing heating energy consumption by 25%.

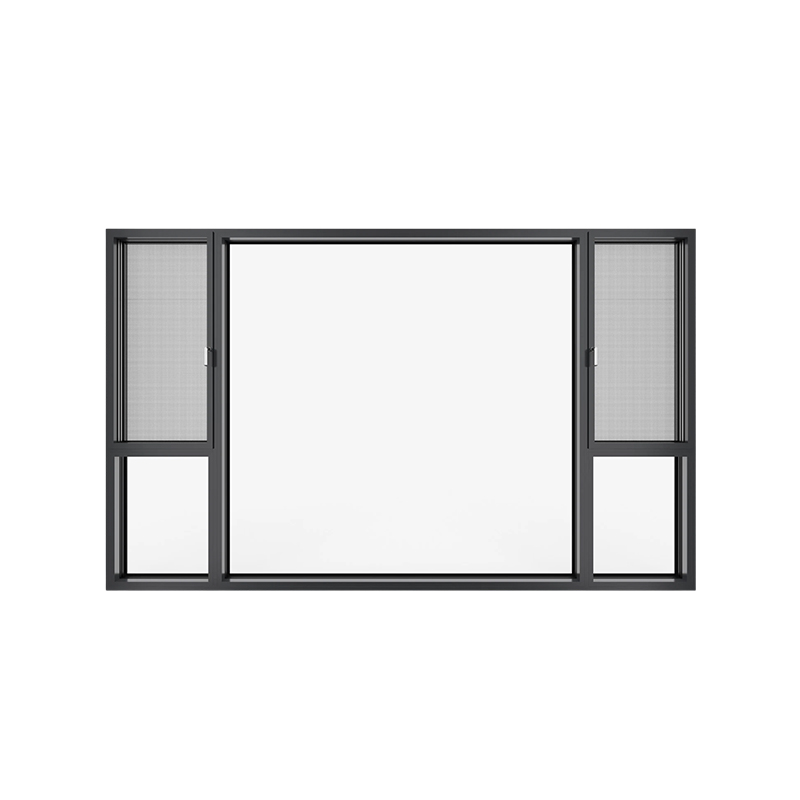

Enhanced Safety: Dual Protection with Inward-Opening and Tilt-In Design

The inward-opening and tilt-in design offers two opening options (90° opening and 15° tilt) to maximize space utilization. When tilted, wind enters from the sides, preventing direct blows on the body and preventing children from climbing and falling. The multi-locking anti-theft structure (eight locking points, top, bottom, left, and right) combined with diamond mesh increases pry resistance by three times and has passed the Ministry of Public Security's GA/T 73-2015 anti-theft certification. In high-rise buildings, the inward-opening design eliminates the risk of falling outward-opening windows, complying with the "Uniform Design Standard for Civil Buildings," which prohibits outward-opening casement windows in buildings over seven stories. After adopting this design in a Beijing high-rise apartment project, window falling incidents have been reduced to zero, and property management complaints have dropped by 90%.

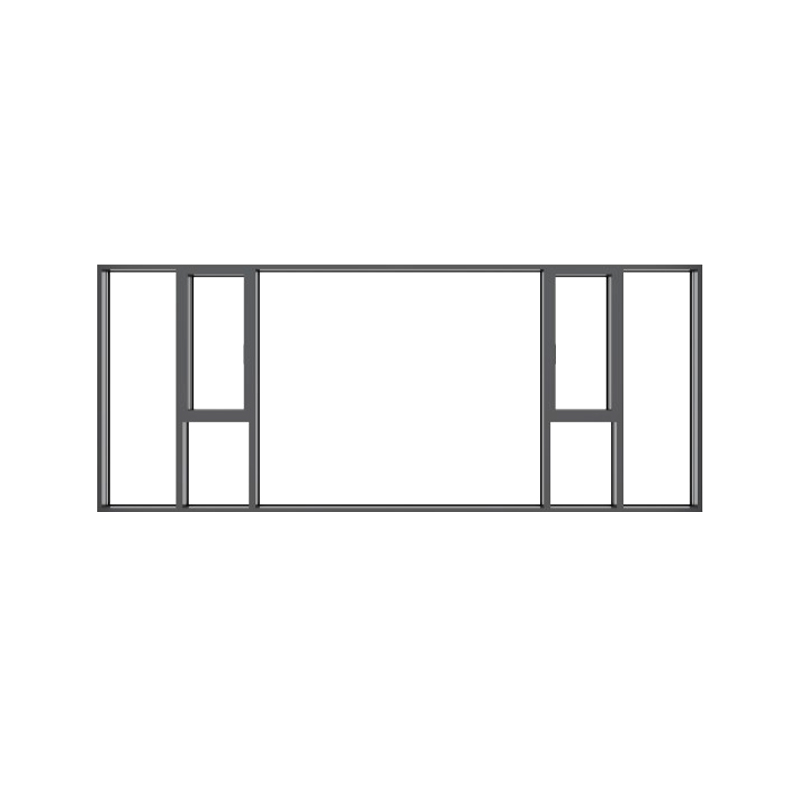

Advanced Technology: Quality Assurance from Internally Installed Crimping and Seamless Welding

The Low Energy Consumption Inward Opening Window System features an internally installed rimming design. The glass fixing rim is located on the interior side, leaving no seams on the exterior side. This seam is directly sealed with sealant, improving waterproofing by 40%, making it particularly suitable for rainy or coastal areas. The seamless welding process ensures that the profile joints achieve 90% of the parent material strength, eliminating the stress concentration associated with traditional corner bracket connections and extending the window frame lifespan to 30 years. Compared to externally installed rimming systems, the internally installed rimming solution reduces high-rise building glazing replacement costs by 60% (no suspended gantry required), while also improving the facade's simplicity by 50%, meeting the "hidden frame" effect desired in high-end residential buildings.

The LEI's aluminum alloy doors and windows have passed authoritative five-performance testing (wind pressure resistance, watertightness, airtightness, thermal insulation, and sound insulation), achieving industry-leading performance. Its wind pressure resistance reaches Level 9 (the highest level), capable of withstanding a Category 12 typhoon; its watertightness reaches Level 6 (the highest level), ensuring no leakage for 10 minutes in a simulated rainstorm; and its airtightness reaches Level 8 (the highest level). Its airflow rate is only 0.5 m³ per square meter per hour, far lower than the 1.5 m³ of ordinary doors and windows. Its thermal insulation performance is also Level 9, with a K value (heat transfer coefficient) as low as 1.1-1.3 W/(m²·K), saving over 60% energy compared to ordinary aluminum alloy windows (K value 6.69-6.84 W/(m²·K)). With a sound insulation rating of Level 4, it can block noise levels exceeding 35 decibels, making it suitable for noise-sensitive areas such as airports and high-speed rail stations. For example, in cold northern regions, the Low Energy Consumption Inward Opening Window System can reduce indoor heating energy consumption by 30%, saving up to 1,500 kWh per household annually.

Structural Innovation: Synergistic Optimization of Quick-Installation Hardware and Thermal Insulation Strips

The Low Energy Consumption Inward Opening Window System utilizes next-generation quick-install concealed hardware technology. Its single sash has a load-bearing capacity of 180 kg, far exceeding the 80 kg limit of traditional hinges, enabling stable installation of large glass expanses (up to 6 square meters). The unique thermal insulation strip design with single or double fins physically blocks the heat transfer channel in the profile, improving its thermal insulation performance by 40% and increasing its bending resistance by three times, effectively addressing the problem of deformation in large windows. The window sash and frame corners are assembled using a pin-injected glue process, achieving a bond strength twice that of traditional corner brackets, ensuring long-term wear and tear, providing dual protection against heavy glass loads and strong winds and heavy rain. The triple-seal + trailing sealant strip structure, with soft-hard co-extruded composite sealant strips (soft for elasticity, hard for durability), improves airtightness by 50%. The trailing design further optimizes thermal insulation and reduces cold bridge formation.

Energy Savings Furthered: Technological Breakthroughs in Triple-Glass, Double-Cavity, and Drainage Systems

The Low Energy Consumption Inward Opening Window System supports a triple-glazed, double-cavity structure (5mm glass + 12mm hollow layer + 5mm glass + 12mm hollow layer + 5mm glass). The K value of the entire window can be reduced to 0.8W/(m²·K), saving 20% compared to double-glazed structures and accommodating temperatures as cold as -30°C. Concealed or high-efficiency exposed drainage channels direct rainwater outdoors through rapid drainage channels, eliminating the clogging problems of traditional exposed drain holes while maintaining a clean facade. For example, in a residential project in Harbin, the adoption of a triple-glazed, double-cavity structure reduced indoor temperature fluctuations from ±5°C to ±1.5°C in winter, reducing heating energy consumption by 25%.

Enhanced Safety: Dual Protection with Inward-Opening and Tilt-In Design

The inward-opening and tilt-in design offers two opening options (90° opening and 15° tilt) to maximize space utilization. When tilted, wind enters from the sides, preventing direct blows on the body and preventing children from climbing and falling. The multi-locking anti-theft structure (eight locking points, top, bottom, left, and right) combined with diamond mesh increases pry resistance by three times and has passed the Ministry of Public Security's GA/T 73-2015 anti-theft certification. In high-rise buildings, the inward-opening design eliminates the risk of falling outward-opening windows, complying with the "Uniform Design Standard for Civil Buildings," which prohibits outward-opening casement windows in buildings over seven stories. After adopting this design in a Beijing high-rise apartment project, window falling incidents have been reduced to zero, and property management complaints have dropped by 90%.

Advanced Technology: Quality Assurance from Internally Installed Crimping and Seamless Welding

The Low Energy Consumption Inward Opening Window System features an internally installed rimming design. The glass fixing rim is located on the interior side, leaving no seams on the exterior side. This seam is directly sealed with sealant, improving waterproofing by 40%, making it particularly suitable for rainy or coastal areas. The seamless welding process ensures that the profile joints achieve 90% of the parent material strength, eliminating the stress concentration associated with traditional corner bracket connections and extending the window frame lifespan to 30 years. Compared to externally installed rimming systems, the internally installed rimming solution reduces high-rise building glazing replacement costs by 60% (no suspended gantry required), while also improving the facade's simplicity by 50%, meeting the "hidden frame" effect desired in high-end residential buildings.