How do low-energy external windows improve their airtightness through multi-layer sealing?

Release Time : 2025-10-23

With modern buildings pursuing energy efficiency, comfort, and health, low-energy external windows are no longer simply openings for light and ventilation; they are now a critical component of the building envelope that influences energy consumption and the indoor environment. Particularly in regions with cold winters or hot summers, poor sealing often allows cold air to penetrate and heat to escape through conventional windows and doors. This not only increases the burden on air conditioning and heating systems but also leads to drafts, condensation, and even mold. In this context, how low-energy external windows improve their airtightness through multi-layer sealing to prevent cold air infiltration and heat loss has become a key factor in measuring their performance.

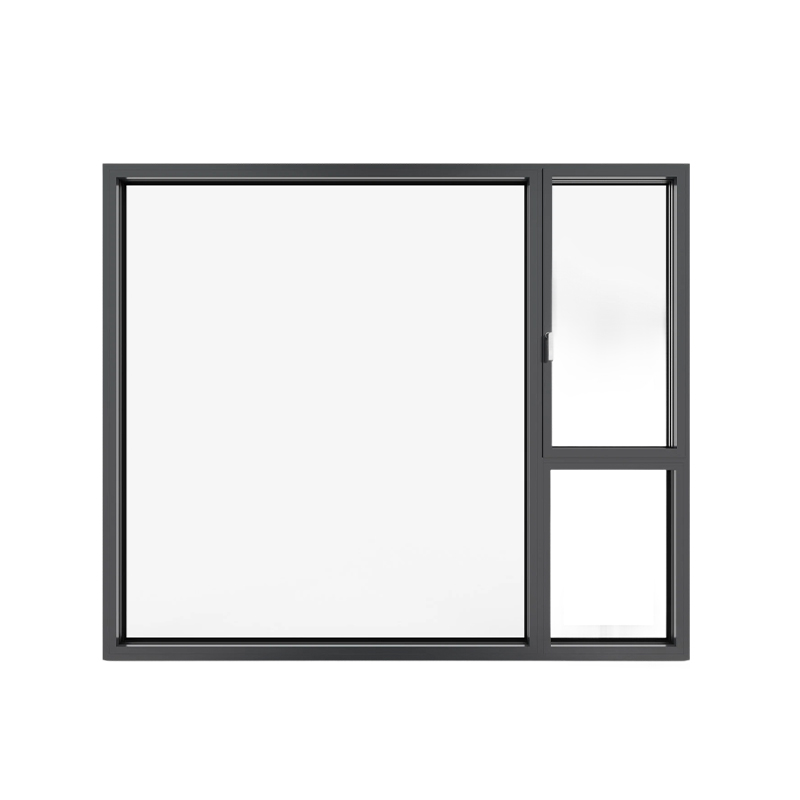

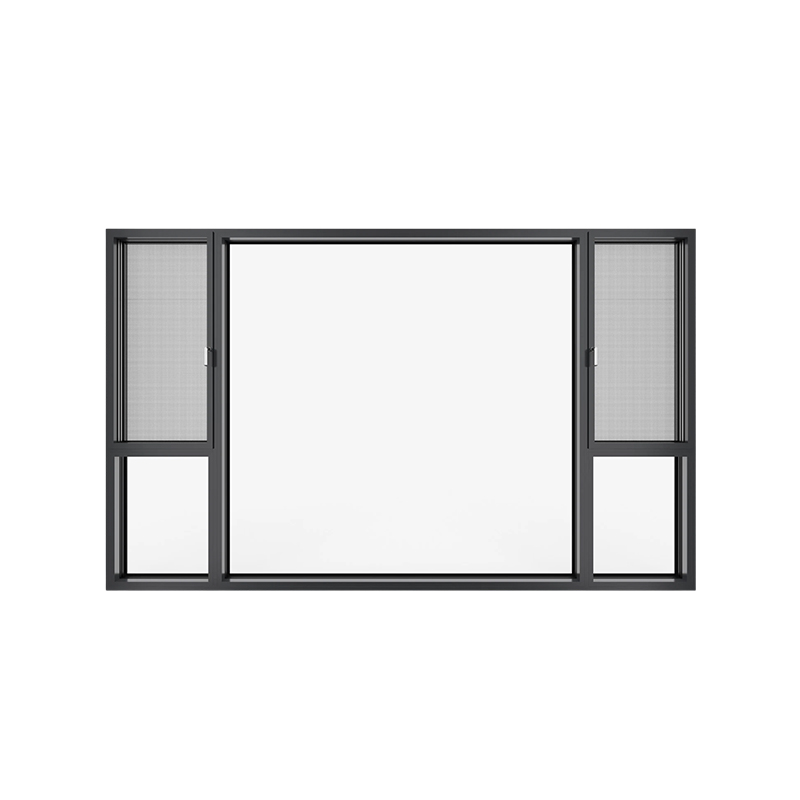

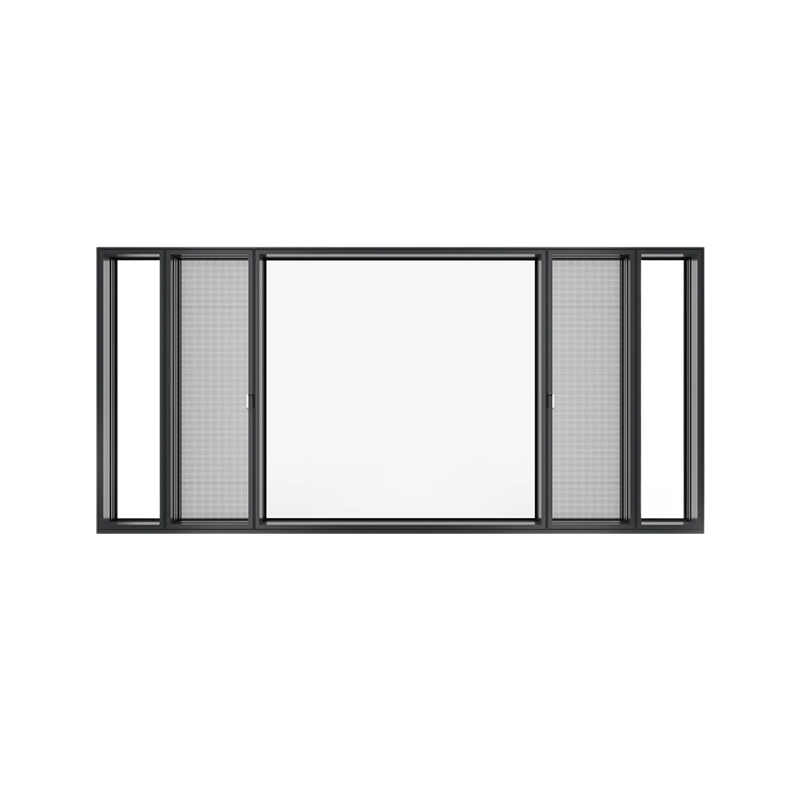

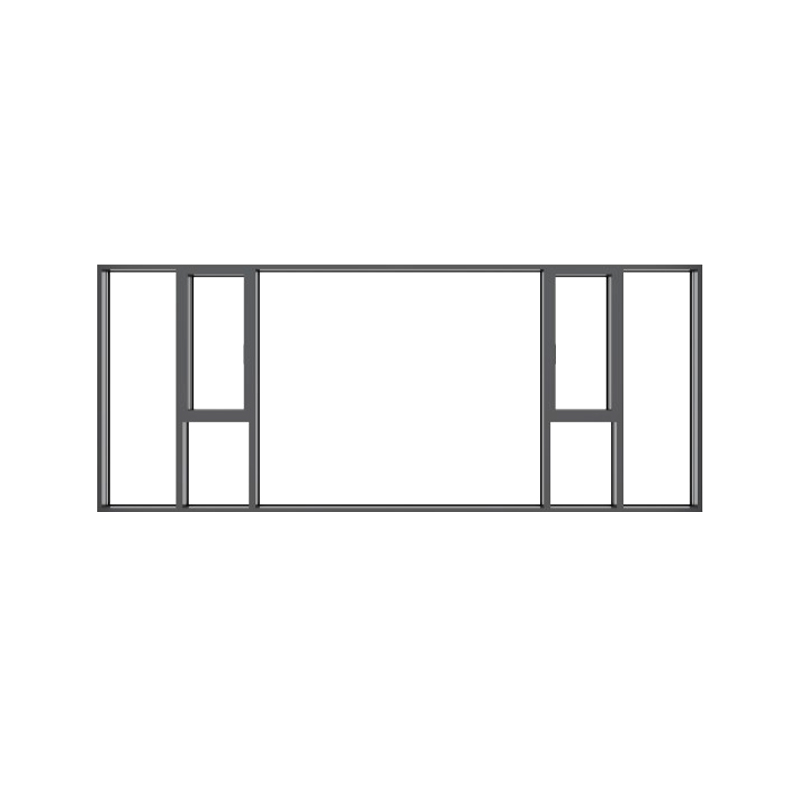

High-quality low-energy external window systems eschew the traditional single-layer sealing method of adhesive strips in favor of a strategically arranged multi-layer sealing structure, creating a progressively more airtight barrier. These sealing systems are typically located at the joint between the window frame and sash, the closing path between the opening sash and the fixed frame, and the junction between the glass and the profile, collectively creating a continuous, tight, and sealed system. When doors and windows are closed, each seal performs its own function: providing windproofing, waterproofing, soundproofing, and thermal insulation, preventing air from easily penetrating indoors and outdoors.

The first seal, often located on the outside, primarily protects against wind and rain. It effectively blocks rainwater from seeping into the wall through gaps and initially weakens the impact of external airflow. The middle seal, the core line of defense for airtightness, is typically made of highly elastic EPDM rubber or siliconized wool. These materials offer excellent resilience and aging resistance, ensuring a tight fit even after prolonged opening and closing. When the window sash is locked, this seal is moderately compressed, creating a highly continuous contact surface and completely blocking airflow. This ensures that indoor and outdoor air exchange occurs only through a controlled ventilation system, rather than through uncontrolled infiltration.

The seal on the inside of a low-energy-consumption external window further enhances insulation, especially during cold weather. It effectively prevents warm indoor air from cooling down near the window, preventing the formation of radiant heat and localized low-temperature zones. This multi-layered, multi-functional sealing layout ensures that even with drastic fluctuations in external wind pressure, the doors and windows maintain a stable airtight seal, preventing gaps from opening due to transient wind forces.

The multi-sealing design extends not only to the horizontal closing surfaces but also to all four edges of the window sash, including the top, bottom, sides, and corner joints. During the manufacturing process, these system doors and windows utilize a continuous bending or integrally molded sealing structure to eliminate joint gaps and ensure a seamless seal around the entire perimeter. Corner joints are precisely glued or mechanically pressed together to prevent seal failure due to thermal expansion, contraction, or structural deformation. This full-circumference closed-loop sealing concept ensures that the doors and windows maintain their initial airtightness even after long-term use.

The effectiveness of the low-energy external window system also relies on the precise fit of the hardware. High-quality locking points ensure uniform compression, ensuring that the window sash is fully aligned with the frame when closed, ensuring that every sealant is fully effective. Advanced opening methods like inward-opening and tilt-to-turn windows can maintain a partially closed seal line during ventilation, achieving a balance between micro-ventilation and high airtightness.

From a living perspective, multi-layer sealing not only brings energy savings but also significantly enhances comfort. Indoor temperatures are more uniform, eliminating the chill near windows. Condensation eliminates window crevices in winter, keeping walls dry and inhibiting mold growth. External noise is effectively isolated, creating a quiet and private living space. Even in windy weather, the interior remains tranquil, without the worry of cold drafts.

More importantly, this sealing design synergizes with thermally insulated aluminum profiles, high-performance glass, and a thermal bridge-free installation process to form a complete low-energy solution. It's not just an isolated technical point, but rather the embodiment of systematic thinking. From material selection to structural design, from factory prefabrication to on-site installation, every step contributes to improving overall airtightness.

In summary, the low-energy consumption external window achieves precise control of air infiltration through a strategically designed multi-layer sealing system. Its layered approach keeps cold air out and warmth in, not only reducing energy consumption but also redefining the comfort standards of modern living. In today's pursuit of green, healthy, and sustainable living, this "invisible barrier" quietly protects the warmth and tranquility of every home.

High-quality low-energy external window systems eschew the traditional single-layer sealing method of adhesive strips in favor of a strategically arranged multi-layer sealing structure, creating a progressively more airtight barrier. These sealing systems are typically located at the joint between the window frame and sash, the closing path between the opening sash and the fixed frame, and the junction between the glass and the profile, collectively creating a continuous, tight, and sealed system. When doors and windows are closed, each seal performs its own function: providing windproofing, waterproofing, soundproofing, and thermal insulation, preventing air from easily penetrating indoors and outdoors.

The first seal, often located on the outside, primarily protects against wind and rain. It effectively blocks rainwater from seeping into the wall through gaps and initially weakens the impact of external airflow. The middle seal, the core line of defense for airtightness, is typically made of highly elastic EPDM rubber or siliconized wool. These materials offer excellent resilience and aging resistance, ensuring a tight fit even after prolonged opening and closing. When the window sash is locked, this seal is moderately compressed, creating a highly continuous contact surface and completely blocking airflow. This ensures that indoor and outdoor air exchange occurs only through a controlled ventilation system, rather than through uncontrolled infiltration.

The seal on the inside of a low-energy-consumption external window further enhances insulation, especially during cold weather. It effectively prevents warm indoor air from cooling down near the window, preventing the formation of radiant heat and localized low-temperature zones. This multi-layered, multi-functional sealing layout ensures that even with drastic fluctuations in external wind pressure, the doors and windows maintain a stable airtight seal, preventing gaps from opening due to transient wind forces.

The multi-sealing design extends not only to the horizontal closing surfaces but also to all four edges of the window sash, including the top, bottom, sides, and corner joints. During the manufacturing process, these system doors and windows utilize a continuous bending or integrally molded sealing structure to eliminate joint gaps and ensure a seamless seal around the entire perimeter. Corner joints are precisely glued or mechanically pressed together to prevent seal failure due to thermal expansion, contraction, or structural deformation. This full-circumference closed-loop sealing concept ensures that the doors and windows maintain their initial airtightness even after long-term use.

The effectiveness of the low-energy external window system also relies on the precise fit of the hardware. High-quality locking points ensure uniform compression, ensuring that the window sash is fully aligned with the frame when closed, ensuring that every sealant is fully effective. Advanced opening methods like inward-opening and tilt-to-turn windows can maintain a partially closed seal line during ventilation, achieving a balance between micro-ventilation and high airtightness.

From a living perspective, multi-layer sealing not only brings energy savings but also significantly enhances comfort. Indoor temperatures are more uniform, eliminating the chill near windows. Condensation eliminates window crevices in winter, keeping walls dry and inhibiting mold growth. External noise is effectively isolated, creating a quiet and private living space. Even in windy weather, the interior remains tranquil, without the worry of cold drafts.

More importantly, this sealing design synergizes with thermally insulated aluminum profiles, high-performance glass, and a thermal bridge-free installation process to form a complete low-energy solution. It's not just an isolated technical point, but rather the embodiment of systematic thinking. From material selection to structural design, from factory prefabrication to on-site installation, every step contributes to improving overall airtightness.

In summary, the low-energy consumption external window achieves precise control of air infiltration through a strategically designed multi-layer sealing system. Its layered approach keeps cold air out and warmth in, not only reducing energy consumption but also redefining the comfort standards of modern living. In today's pursuit of green, healthy, and sustainable living, this "invisible barrier" quietly protects the warmth and tranquility of every home.